- G0-G1: Linear Move

- G2-G3: Arc or Circle Move

- G4: Dwell

- G5: Bézier Cubic Spline Move

- G6: Direct Stepper Move

- G10: Retract

- G11: Recover

- G12: Clean the Nozzle

- G17-G19: CNC Workspace Planes

- G20: Inch Units

- G21: Millimeter Units

- G26: Mesh Validation Pattern

- G27: Park toolhead

- G28: Auto Home

- G29: Bed Leveling

- G29: Bed Leveling (3-Point)

- G29: Bed Leveling (Linear)

- G29: Bed Leveling (Manual)

- G29: Bed Leveling (Bilinear)

- G29: Bed Leveling (Unified)

- G30: Single Z-Probe

- G31: Dock Sled

- G32: Undock Sled

- G33: Delta Auto Calibration

- G34: Z Steppers Auto-Alignment

- G34: Mechanical Gantry Calibration

- G35: Tramming Assistant

- G38.2-G38.5: Probe target

- G42: Move to mesh coordinate

- G53: Move in Machine Coordinates

- G54-G59.3: Select Workspace

- G60: Stored Positions

- G61: Return to Saved Position

- G76: Probe temperature calibration

- G80: Cancel Current Motion Mode

- G90: Absolute Positioning

- G91: Relative Positioning

- G92: Set Position

- G425: Backlash Calibration

- M0-M1: Unconditional stop

- M3: Spindle CW / Laser On

- M4: Spindle CCW / Laser On

- M5: Spindle / Laser Off

- M7-M9: Coolant Controls

- M10-M11: Vacuum / Blower Control

- M16: Expected Printer Check

- M17: Enable Steppers

- M18, M84: Disable steppers

- M20: List SD Card

- M21: Init SD card

- M22: Release SD card

- M23: Select SD file

- M24: Start or Resume SD print

- M25: Pause SD print

- M26: Set SD position

- M27: Report SD print status

- M28: Start SD write

- M29: Stop SD write

- M30: Delete SD file

- M31: Report Print Time

- M32: Select and Start

- M33: Get Long Path

- M34: SDCard Sorting

- M42: Set Pin State

- M43: Pins Debugging

- M43 T: Toggle Pins

- M48: Probe Repeatability Test

- M73: Set Print Progress

- M75: Start Print Job Timer

- M76: Pause Print Job Timer

- M77: Stop Print Job Timer

- M78: Print Job Stats

- M80: Power On

- M81: Power Off

- M82: E Absolute

- M83: E Relative

- M85: Inactivity Shutdown

- M86: Hotend Idle Timeout

- M87: Disable Hotend Idle Timeout

- M92: Set Axis Steps-per-unit

- M100: Free Memory

- M102: Configure Bed Distance Sensor

- M104: Set Hotend Temperature

- M105: Report Temperatures

- M106: Set Fan Speed

- M107: Fan Off

- M108: Break and Continue

- M109: Wait for Hotend Temperature

- M110: Set / Get Line Number

- M111: Debug Level

- M112: Full Shutdown

- M113: Host Keepalive

- M114: Get Current Position

- M115: Firmware Info

- M117: Set LCD Message

- M118: Serial print

- M119: Endstop States

- M120: Enable Endstops

- M121: Disable Endstops

- M122: TMC Debugging

- M123: Fan Tachometers

- M125: Park Head

- M126: Baricuda 1 Open

- M127: Baricuda 1 Close

- M128: Baricuda 2 Open

- M129: Baricuda 2 Close

- M140: Set Bed Temperature

- M141: Set Chamber Temperature

- M143: Set Laser Cooler Temperature

- M145: Set Material Preset

- M149: Set Temperature Units

- M150: Set RGB(W) Color

- M154: Position Auto-Report

- M155: Temperature Auto-Report

- M163: Set Mix Factor

- M164: Save Mix

- M165: Set Mix

- M166: Gradient Mix

- M190: Wait for Bed Temperature

- M191: Wait for Chamber Temperature

- M192: Wait for Probe temperature

- M193: Wait For Laser Cooler Temperature

- M200: Volumetric Extrusion Diameter

- M201: Print / Travel Move Limits

- M203: Set Max Feedrate

- M204: Set Starting Acceleration

- M205: Set Advanced Settings

- M206: Set Home Offsets

- M207: Firmware Retraction Settings

- M208: Firmware Recover Settings

- M209: Set Auto Retract

- M210: Homing Feedrate

- M211: Software Endstops

- M217: Filament swap parameters

- M218: Set Hotend Offset

- M220: Set Feedrate Percentage

- M221: Set Flow Percentage

- M226: Wait for Pin State

- M240: Trigger Camera

- M250: LCD Contrast

- M255: LCD Sleep/Backlight Timeout

- M256: LCD Brightness

- M260: I2C Send

- M261: I2C Request

- M265: Scan I2C Bus

- M280: Servo Position

- M281: Edit Servo Angles

- M282: Detach Servo

- M290: Babystep

- M300: Play Tone

- M301: Set Hotend PID

- M302: Cold Extrude

- M303: PID autotune

- M304: Set Bed PID

- M305: User Thermistor Parameters

- M306: Model Predictive Temp. Control

- M309: Set Chamber PID

- M350: Set micro-stepping

- M351: Set Microstep Pins

- M355: Case Light Control

- M360: SCARA Theta A

- M361: SCARA Theta-B

- M362: SCARA Psi-A

- M363: SCARA Psi-B

- M364: SCARA Psi-C

- M380: Activate Solenoid

- M381: Deactivate Solenoids

- M400: Finish Moves

- M401: Deploy Probe

- M402: Stow Probe

- M403: MMU2 Filament Type

- M404: Filament Width Sensor Nominal Diameter

- M405: Filament Width Sensor On

- M406: Filament Width Sensor Off

- M407: Read Filament Width

- M410: Quickstop

- M412: Filament Runout

- M413: Power-loss Recovery

- M414: LCD language

- M420: Bed Leveling State

- M421: Set Mesh Value

- M422: Set Z Motor XY

- M423: X Twist Compensation

- M425: Backlash compensation

- M428: Home Offsets Here

- M430: Power Monitor

- M486: Cancel Objects

- M493: Fixed-Time Motion

- M494: FT Motion Trajectory Smoothing

- M500: Save Settings

- M501: Restore Settings

- M502: Factory Reset

- M503: Report Settings

- M504: Validate EEPROM contents

- M510: Lock Machine

- M511: Unlock Machine

- M512: Set Passcode

- M524: Abort SD print

- M540: Endstops Abort SD

- M550: Machine Name

- M552: Ethernet IP Address, Network IF

- M553: Ethernet Subnet Mask

- M554: Ethernet Gateway IP Address

- M569: Set TMC Stepping Mode

- M575: Serial baud rate

- M592: Nonlinear Extrusion Control

- M593: ZV Input Shaping

- M600: Filament Change

- M603: Configure Filament Change

- M605: Multi Nozzle Mode

- M665: Delta Configuration

- M665: SCARA Configuration

- M666: Set Delta endstop adjustments

- M666: Dual endstop offsets

- M672: Duet Smart Effector sensitivity

- M701: Load filament

- M702: Unload filament

- M710: Controller Fan settings

- M808: Repeat Marker

- M810-M819: G-code macros

- M820: Report G-code macros

- M851: XYZ Probe Offset

- M852: Bed Skew Compensation

- M860-M869: I2C Position Encoders

- M871: Probe temperature config

- M876: Handle Prompt Response

- M900: Linear Advance Factor

- M906: Stepper Motor Current

- M907: Trimpot Stepper Motor Current

- M908: Set Trimpot Pins

- M909: Report DAC Stepper Current

- M910: Commit DAC to EEPROM

- M911: TMC OT Pre-Warn Condition

- M912: Clear TMC OT Pre-Warn

- M913: Set Hybrid Threshold Speed

- M914: TMC Bump Sensitivity

- M915: TMC Z axis calibration

- M916: L6474 Thermal Warning Test

- M917: L6474 Overcurrent Warning Test

- M918: L6474 Speed Warning Test

- M919: TMC Chopper Timing

- M920: TMC Homing Current

- M928: Start SD Logging

- M951: Magnetic Parking Extruder

- M993: Back up flash settings to SD

- M994: Restore flash from SD

- M995: Touch Screen Calibration

- M997: Firmware update

- M999: STOP Restart

- M7219: MAX7219 Control

- T0-T7: Select or Report Tool

- T?-Tx: MMU2 Special Commands

Description

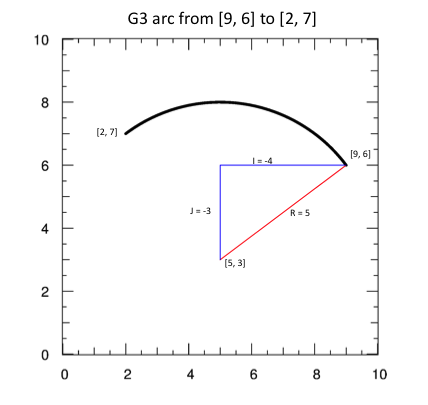

G2 adds a clockwise arc move to the planner; G3 adds a counter-clockwise arc. An arc move starts at the current position and ends at the given XYZ, pivoting around a center-point offset given by I and J or R.

CNC_WORKSPACE_PLANES allows G2/G3 to operate in the selected XY, ZX, or YZ workspace plane.

This command has two forms:

I J Form

-

Ispecifies an X offset.Jspecifies a Y offset. - At least one of the

IJparameters is required. -

XandYcan be omitted to do a complete circle. - The given

XYis not error-checked. The arc ends based on the angle of the destination. - Mixing

IorJwithRwill throw an error.

R Form

-

Rspecifies the radius.XorYis required. - Omitting both

XandYwill throw an error. -

XorYmust differ from the current XY position. - Mixing

RwithIorJwill throw an error.

Arc moves actually generate several short straight-line moves, the length of which are determined by the configuration option MM_PER_ARC_SEGMENT (default 1mm). Any change in the position on the Z, A, B, C, U, V, and W axes is linearly interpolated over the whole arc.

‘ARC_P_CIRCLES’ enables the use of the ‘P’ parameter to specify complete circles

Usage

G2 [A<pos>] [B<pos>] [C<pos>] [E<pos>] [F<rate>] I<offset> J<offset> [P<count>] R<radius> [S<power>] [U<pos>] [V<pos>] [W<pos>] [X<pos>] [Y<pos>] [Z<pos>] G3 [A<pos>] [B<pos>] [C<pos>] [E<pos>] [F<rate>] I<offset> J<offset> [P<count>] R<radius> [S<power>] [U<pos>] [V<pos>] [W<pos>] [X<pos>] [Y<pos>] [Z<pos>] Parameters

[A<pos>] 2.0.9 I_DRIVER_TYPE AXIS4_NAME 'A' | A coordinate on the A axis |

[B<pos>] 2.0.9 J_DRIVER_TYPE AXIS5_NAME 'B' | A coordinate on the B axis |

[C<pos>] 2.0.9 K_DRIVER_TYPE AXIS6_NAME 'C' | A coordinate on the C axis |

[E<pos>] | The amount to extrude between the start point and end point |

[F<rate>] | The nominal movement rate. For moves involving all primary axes (XYZ), the feed rate is applied along the helical trajectory. The feedrate set here applies to subsequent moves that omit this parameter. Feedrate is interpreted according to the specification for LinuxCNC default state (trivial kinematics, |

I<offset> | An offset from the current X position to use as the arc center |

J<offset> | An offset from the current Y position to use as the arc center |

[P<count>]ARC_P_CIRCLES | Specify complete circles. |

R<radius> | A radius from the current XY position to use as the arc center |

[S<power>] 2.0.8 | Set the Laser power for the move. |

[U<pos>] 2.1 U_DRIVER_TYPE AXIS7_NAME 'U' | A coordinate on the U axis |

[V<pos>] 2.1 V_DRIVER_TYPE AXIS8_NAME 'V' | A coordinate on the V axis |

[W<pos>] 2.1 W_DRIVER_TYPE AXIS9_NAME 'W' | A coordinate on the W axis |

[X<pos>] | A coordinate on the X axis |

[Y<pos>] | A coordinate on the Y axis |

[Z<pos>] | A coordinate on the Z axis |

Gallery

G3 command geometry

This illustrates a counter clockwise arc, starting at [9, 6]. It can be generated either by G3 X2 Y7 I-4 J-3 or G3 X2 Y7 R5

Examples

Move in a clockwise arc from the current position to [125, 32] with the center offset from the current position by (10.5, 10.5).

G2 X125 Y32 I10.5 J10.5Move in a counter-clockwise arc from the current position to [125, 32] with the center offset from the current position by (10.5, 10.5).

G3 X125 Y32 I10.5 J10.5Move in a complete clockwise circle with the center offset from the current position by [20, 20].

G2 I20 J20